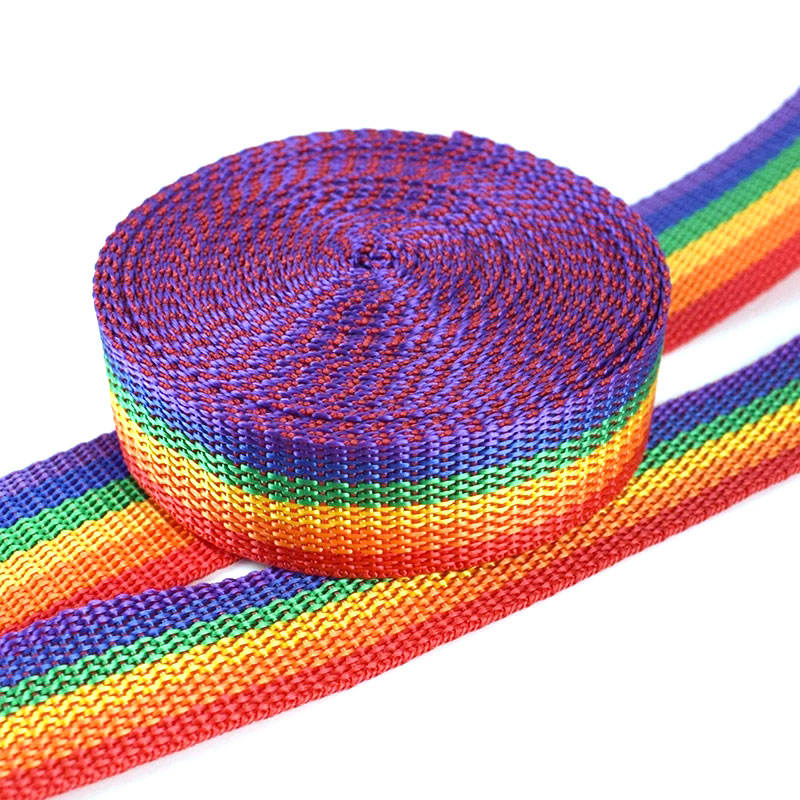

PP webbing, crafted from polypropylene fibers, stands as a versatile and cost-effective strapping material with a wide array of applications. Renowned for its exceptional strength-to-weight ratio, this flat and sturdy webbing offers reliable load-bearing capabilities while remaining lightweight.

One of the standout features of PP webbing is its resistance to moisture, chemicals, and UV radiation. This property makes it well-suited for outdoor and marine applications, where exposure to harsh elements is common. Additionally, its low water absorption prevents deterioration and maintains its performance over time.

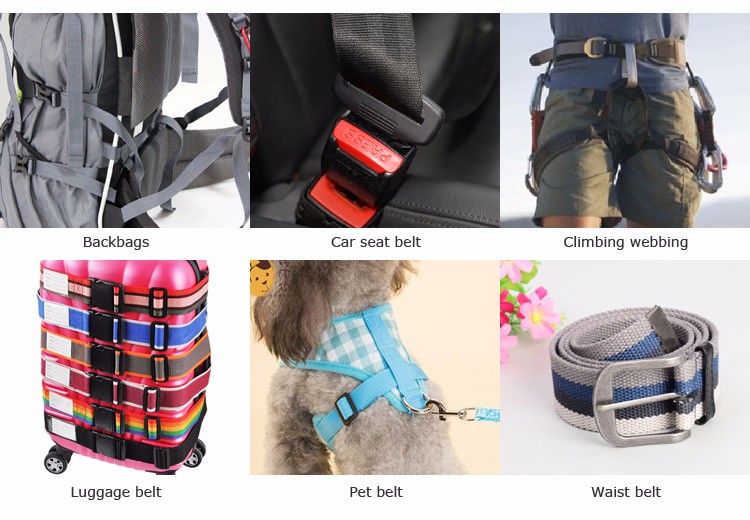

PP webbing is widely employed in industries such as luggage, backpacks, safety gear, and even agriculture. Its customizable options, including various colors and widths, allow manufacturers to tailor it to their specific needs. Its affordability makes it a preferred choice for high-volume production.

While not as soft as some other materials, PP webbing offers remarkable durability, making it ideal for tasks that demand robust strapping solutions. It can be easily sewn, heat-sealed, or attached with hardware, ensuring seamless integration into diverse products and uses.

In summary, PP webbing’s blend of strength, resistance, and economic viability positions it as a valuable component across industries seeking dependable and budget-friendly strapping and securing solutions.